Researchers reveal mechanism of fatigue damage by high thermal loads in tungsten composites

The relationship between microstructure evolution and property degradation of two representative second-phase dispersion strengthened tungsten materials after electron beam thermal loading was investigated recently by a collaborated research team from Hefei Institutes of Physical Science (HFIPS), Chinese Academy of Sciences (CAS).

The related research was published in Journal of Materials Science & Technology.

The best environment for human survival is 25 ℃. The plasma-facing tungsten (W) materials in the magnetic confinement nuclear fusion devices, however, are directly exposed to high-temperature plasma and are typically subjected to steady-state thermal loads of 5–20 MW/m2 and transient thermal shocks of ~1 GW/m2, which can raise the surface temperature of tungsten to above 1800 ℃. The high heat flux load to W leads to some irreversible material damages, such as surface roughening, cracking and surface melting. Therefore, it is urgent to evaluate the thermal load resistance of W materials.

In this study, researchers carried out repetitive heat loads on an electron beam device 30 kW Electron-beam Material-research Platform (EBMP-30). This platform was specially built to evaluate the thermal shock resistance of plasma-facing materials (PFMs).

“It adopts a 30 kW welding electron beam with a maximum acceleration voltage of 100 kV,” explained XIE Zhuoming, who helped to build the platform, “it can scan 30 × 30 mm2 area with maximal frame rate of 35 kHz, and its pulse duration can change from 100 ms to a continuous state.”

Based on the EBMP-30 device, two representative W-0.5wt% ZrC (WZC) and W-1.0wt% Y2O3 (WYO) composites were selected to study the damage behavior induced by repeated steady-state heat loads with absorbed power density (APD) in the range of 10–30 MW/m2.

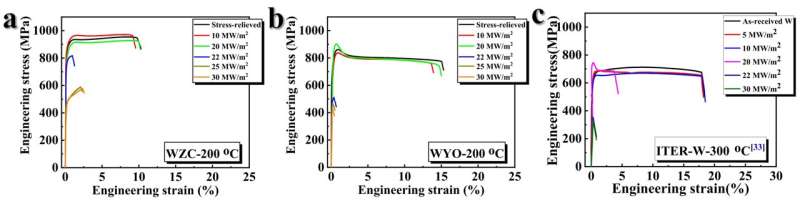

The results show that the microstructures and tensile properties of WZC and WYO specimens do not change significantly when APD ≤ 20 MW/m2. However, when APD ≥ 22 MW/m2, full recrystallization and grain growth in WYO specimens and Y2O3 particles shedding from the W matrix were detected.

Moreover, the ultimate tensile strength and total elongation of WYO decreased from 861 MPa to 510 MPa and from 15% to near zero, respectively.

“Due to the different coefficients of thermal expansion (CTEs) of the Y2O3 phase and W, irreversible plastic deformation of the W matrix occurs, especially around the coarse Y2O3 particles,” said Wu Xuebang, who led the team, “which leads to the interface debonding between Y2O3 particles and the W matrix.”

After thermal loads at 22 MW/m2, WZC specimens maintained the high ultimate tensile strength of 816 MPa due to its high recrystallization temperature (~1300 ℃).

“The fine and uniform distribution of ZrC particles and its comparable CTE to the W matrix,” Wu added, “which effectively avoids ZrC particle shedding and the formation of microcracks.”

“This study reveals the correlations between the microstructure evolution and performance degradation in two representative second-phase dispersion strengthened tungsten materials, as well as the mechanism of fatigue damage by high thermal loads,” said WU, “which provides an important reference for the further development of high-performance tungsten materials.”

More information:

Hui Wang et al, Microstructural evolution and thermal fatigue damage mechanism of second-phase dispersion strengthened tungsten composites under repetitive thermal loads, Journal of Materials Science & Technology (2022). DOI: 10.1016/j.jmst.2022.09.007

Citation:

Researchers reveal mechanism of fatigue damage by high thermal loads in tungsten composites (2023, January 6)

retrieved 6 January 2023

from https://phys.org/news/2023-01-reveal-mechanism-fatigue-high-thermal.html

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no

part may be reproduced without the written permission. The content is provided for information purposes only.

For all the latest Science News Click Here

For the latest news and updates, follow us on Google News.