KISS method for 2D material preparation: Unlocking new possibilities for materials science

It has almost been 20 years since the establishment of the field of two-dimensional (2D) materials with the discovery of unique properties of graphene, a single, atomically thin layer of graphite. The significance of graphene and its one-of-a-kind properties was recognized as early as 2010 when the Nobel prize in physics was awarded to A. Geim and K. Novoselov for their work on graphene. However, graphene has been around for a while, though researchers simply did not realize what it was, or how special it is (often, it was considered annoying dirt on nice, clean surfaces of metals REF). Some scientists even dismissed the idea that 2D materials could exist in our three-dimensional world.

Today, things are different. 2D materials are one of the most exciting and fascinating subjects of study for researchers from many disciplines, including physics, chemistry and engineering. 2D materials are not only interesting from a scientific point of view, they are also extremely interesting for industrial and technological applications, such as touchscreens and batteries.

We are also getting very good at discovering and preparing new 2D materials, and the list of known and available 2D materials is rapidly expanding. The 2D materials family is getting very large and graphene is not alone anymore. Instead, it now has a lot of 2D relatives with different properties and vastly diverse applications, predicted or already achieved.

Nevertheless, one thing has not changed much since early 2000s, and that is the way we make graphene and other 2D materials. The first method used to make graphene, using a sticky tape, is still the most popular method to make 2D materials as it provides 2D materials of highest quality. This conventional method, however, does have some drawbacks: usually, the resulting 2D flakes are very small, and the tape leaves behind glue and polymer residues on the substrate where the 2D material is deposited. While this drawback is manageable for many studies, it is not desirable in my field, surface science. In this field, we have strict cleanliness requirements and the need for larger 2D materials than samples produced with a sticky tape.

This necessitates a different approach, for example, growth of materials directly in ultra-high vacuum. But this is also not ideal—it often takes a very long time to come up with the right “recipe,” and some materials simply cannot be grown on all of the substrates.

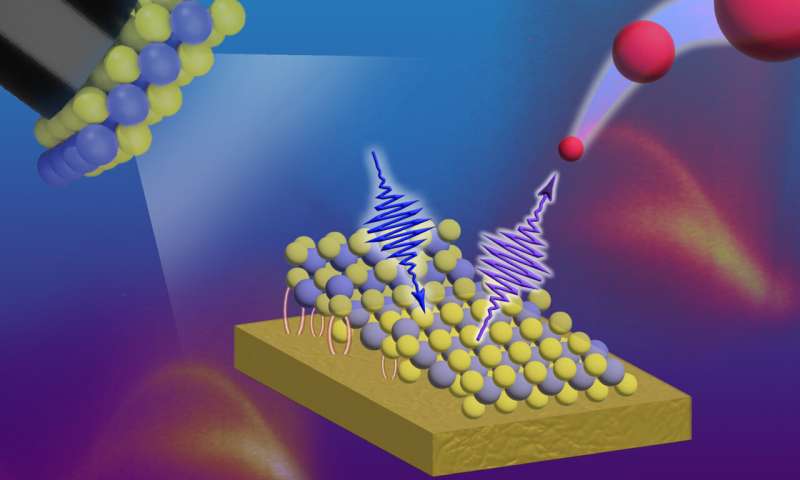

For this reason, we came up with a new method to produce 2D materials, kinetic in situ single-layer synthesis, or the KISS method. Our research is published in the journal Advanced Science.

How can we make 2D materials in a simpler and cleaner way?

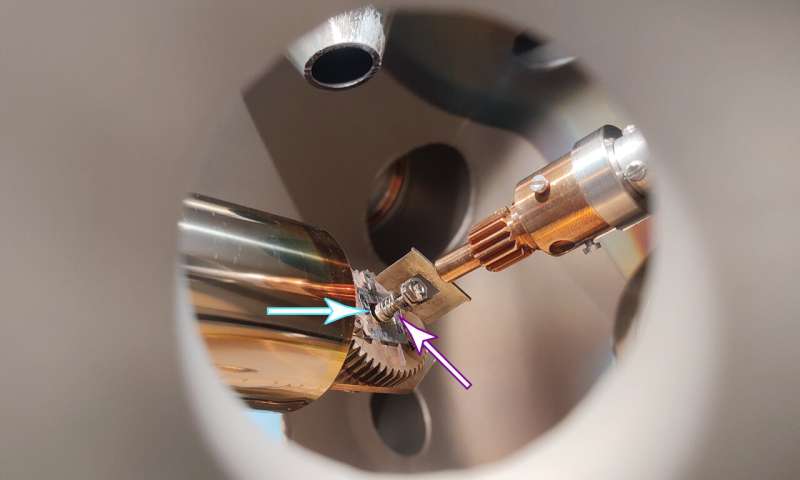

But how does the KISS method produce materials in a simple, but cleaner way? One advantage lies in the realm of surface science, where most of the work is done under ultra-high vacuum conditions. You probably know about vacuum, a space or a container devoid of matter, including even atoms. In reality, it is simply a region of space with pressure lower than atmospheric pressure. The lower the pressure, the less matter occupying that space or container. Ultra-high vacuum is exactly that, a region of extremely low pressure, akin to the vacuum of space. In this low-pressure chamber, the presence of atoms and molecules is significantly reduced, so I can keep my samples clean and for a long time. Ultra-high vacuum and cleanliness is one of the fundamental ingredients in the KISS exfoliation process.

Another key ingredient is the use of exceptionally flat and clean substrate on which the 2D material is placed. The substrate can be a metal like gold or silver, or even a semiconductor such as germanium, as long as it is atomically flat and clean. To keep things simple, the substrate is also used for exfoliation as a sort of a stiff sticky tape.

These are some of the main reasons why KISS exfoliation works so well. My “sticky tape” substrate is extremely flat, and extremely clean, which facilitates excellent contact with the entire crystal surface, allowing a 2D material to stick well to the substrate.

How simple is this to do, really? For researchers working in surface science labs, this method proves to be incredibly simple. We always do things in ultra-high vacuum, and know how to clean things well, so that part is easy. The substrates that are used, single crystal Ag(111) or Au(111), are also commonly used for calibration of surface science equipment, so they are also often found in surface science laboratories. The only additional requirement is attaching the layered crystal to a holder with a spring-like mechanism, similar to the one from a pen, ensuring a gentle and precise contact during the KISS exfoliation process.

The dawn of the KISS method

So how applicable is the KISS method? In our research paper detailing the KISS method, my colleagues and I conducted extensive tests using several materials and three types of substrates, and we prepared 2D layers from four layered materials. We did these experiments in two separate laboratories in Sweden and Denmark, and even tested multiple holder designs to assess the method’s versatility. The results are promising—it turns out, quite a lot! With KISS exfoliation we could prepare many different 2D materials, and the setup is easily adaptable in different laboratory settings. We have successfully implemented it in my research group at the University of Groningen, and several of my collaborators from other research institutes have successfully applied it despite working with a completely different setup and studying different materials. Given its simplicity and suitability for surface science, particularly for materials sensitive to air, the KISS method has the potential to revolutionize the production and study of 2D materials.

My hope is that researchers in the field of surface science around the world, and perhaps even in other disciplines, will adopt and adapt this method for their research, making their experiments easier and faster. Who knows? In the future, we may even be able to adapt the KISS method for large-scale production of 2D materials.

This story is part of Science X Dialog, where researchers can report findings from their published research articles. Visit this page for information about ScienceX Dialog and how to participate.

More information:

Antonija Grubišić‐Čabo et al, In Situ Exfoliation Method of Large‐Area 2D Materials, Advanced Science (2023). DOI: 10.1002/advs.202301243

Antonija Grubišić-Čabo is an Assistant Professor at the Zernike Institute for Advanced Materials of the University of Groningen. She is the principal investigator (PI) of the research group “Experimental nanophysics with advanced spectroscopic and structural analysis methods,” studying electronic and structural properties of nanomaterials in and out of equilibrium. Her main research interests are two-dimensional (2D) and quantum materials, such as graphene, 2D transition metal dichalcogenides and topological insulators, which she studies with spectroscopy techniques such as angle-resolved photoemission spectroscopy (ARPES) and time-resolved ARPES.

Citation:

KISS method for 2D material preparation: Unlocking new possibilities for materials science (2023, June 9)

retrieved 9 June 2023

from https://phys.org/news/2023-06-method-2d-material-possibilities-materials.html

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no

part may be reproduced without the written permission. The content is provided for information purposes only.

For all the latest Science News Click Here

For the latest news and updates, follow us on Google News.