Finite state machine implemented as pneumatic circuit using microfluidic valves to create lab-on-a-chip

A group of biochemical engineers, Siavash Ahrar, Manasi Raje, Irene Lee and Elliot Hui at the University of California, Irvine, has developed a finite state machine (FSM) implemented as a pneumatic circuit using microfluidic valves to build a lab-on-a-chip. Their work is published in the journal Science Advances.

Over the past several years, biochemical and mechanical engineers have been working toward the goal of automating many of the chemical process that are currently done by hand—trained lab technicians using pipettes to determine the concentration of a chemical dissolved in a liquid, for example. Automating such tasks would not only make them less expensive, it could speed things up, potentially offering medical lab results in minutes rather than hours. To that end, engineers have been working toward building what they call a lab-on-a-chip. In this new effort, the research team has applied pneumatics to the problem.

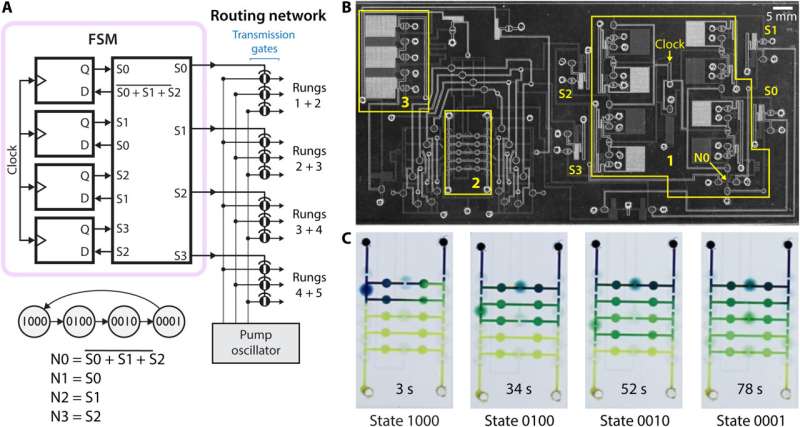

Many chemical processes involve the movement of liquids. The researchers sought to use water pressure instead of electricity when building circuits for use on a potential lab-on-a-chip. They created a tiny sandwich comprising panes of glass as the bread and a sheet of silicone as the interior. But before making their sandwich, they etched the glass panes to allow a liquid to pass through and poked holes in the silicone sheet to connect the channels in the glass panes.

To represent the familiar zeroes and ones used in FSMs, the team used pressure—regular atmospheric pressure represented a zero and vacuum induced pressure represented a one. The coding programs were accomplished by poking holes in the silicone sheet reminiscent of the punch cards used in the early days of computers.

The team then tested their idea by creating a simple four-bit lab-on-a-chip, programmed to conduct serial dilution—determining the concentration of a chemical in a solution. The team showed that microfluidic devices like theirs could someday be used for such purposes as testing blood not just for viruses like SARS-CoV-2, but their concentrations.

More information:

Siavash Ahrar et al, Pneumatic computers for embedded control of microfluidics, Science Advances (2023). DOI: 10.1126/sciadv.adg0201

© 2023 Science X Network

Citation:

Finite state machine implemented as pneumatic circuit using microfluidic valves to create lab-on-a-chip (2023, June 5)

retrieved 5 June 2023

from https://phys.org/news/2023-06-finite-state-machine-pneumatic-circuit.html

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no

part may be reproduced without the written permission. The content is provided for information purposes only.

For all the latest Science News Click Here

For the latest news and updates, follow us on Google News.