Chinese scientists report starch synthesis from carbon dioxide

Chinese scientists recently reported a de novo route for artificial starch synthesis from carbon dioxide (CO2) for the first time. Relevant results were published in Science on Sept. 24.

The new route makes it possible to shift the mode of starch production from traditional agricultural planting to industrial manufacturing, and opens up a new technical route for synthesizing complex molecules from CO2.

Starch is the major component of grain as well as an important industrial raw material. At present, it is mainly produced by crops such as maize by fixing CO2 through photosynthesis. This process involves about 60 biochemical reactions as well as complex physiological regulation. The theoretical energy conversion efficiency of this process is only about 2%.

Strategies for the sustainable supply of starch and use of CO2 are urgently needed to overcome major challenges of mankind, such as the food crisis and climate change. Designing novel routes other than plant photosynthesis for converting CO2 to starch is an important and innovative S&T mission and will be a significant disruptive technology in today’s world.

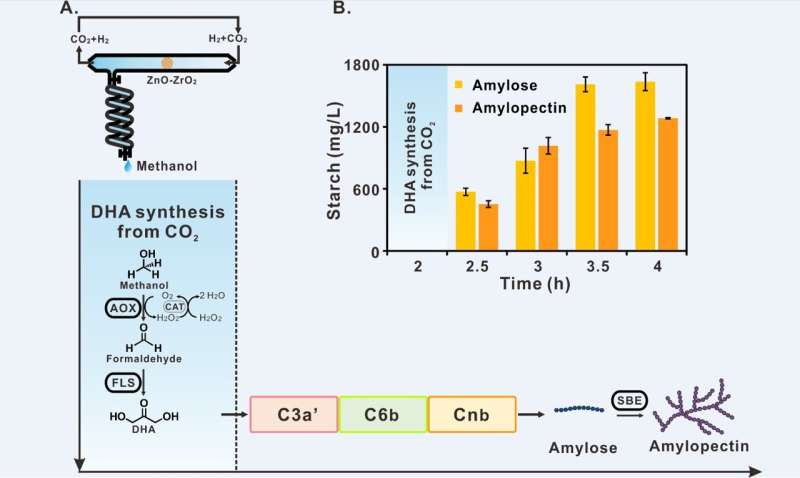

To address this issue, scientists at the Tianjin Institute of Industrial Biotechnology (TIB) of the Chinese Academy of Sciences (CAS) designed a chemoenzymatic system as well as an artificial starch anabolic route consisting of only 11 core reactions to convert CO2 into starch.

This route was established by a “building block” strategy, in which the researchers integrated chemical and biological catalytic modules to utilize high-density energy and high-concentration CO2 in a biotechnologically innovative way.

The researchers systematically optimized this hybrid system using spatial and temporal segregation by addressing issues such as substrate competition, product inhibition, and thermodynamical adaptation.

The artificial route can produce starch from CO2 with an efficiency 8.5-fold higher than starch biosynthesis in maize, suggesting a big step towards going beyond nature. It provides a new scientific basis for creating biological systems with unprecedented functions.

“According to the current technical parameters, the annual production of starch in a one-cubic-meter bioreactor theoretically equates with the starch annual yield from growing 1/3 hectare of maize without considering the energy input,” said Cai Tao, lead author of the study.

This work would open a window for industrial manufacturing of starch from CO2.

“If the overall cost of the process can be reduced to a level economically comparable with agricultural planting in the future, it is expected to save more than 90% of cultivated land and freshwater resources,” said MA Yanhe, corresponding author of the study.

In addition, it would also help to avoid the negative environmental impact of using pesticides and fertilizers, improve human food security, facilitate a carbon-neutral bioeconomy, and eventually promote the formation of a sustainable bio-based society.

TIB has focused on artificial starch biosynthesis and CO2 utilization since 2015. To carry out such demand-oriented S&T research, all kinds of resources for innovation have been gathered together and the integration of “discipline, task and platform” has been strengthened to achieve efficient coordination of research efforts.

Illuminating the mechanism behind how plants regulate starch synthesis

Cai Tao et al, Cell-free chemoenzymatic starch synthesis from carbon dioxide, Science (2021). DOI: 10.1126/science.abh4049

Citation:

Chinese scientists report starch synthesis from carbon dioxide (2021, September 23)

retrieved 23 September 2021

from https://phys.org/news/2021-09-chinese-scientists-starch-synthesis-carbon.html

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no

part may be reproduced without the written permission. The content is provided for information purposes only.

For all the latest Science News Click Here

For the latest news and updates, follow us on Google News.