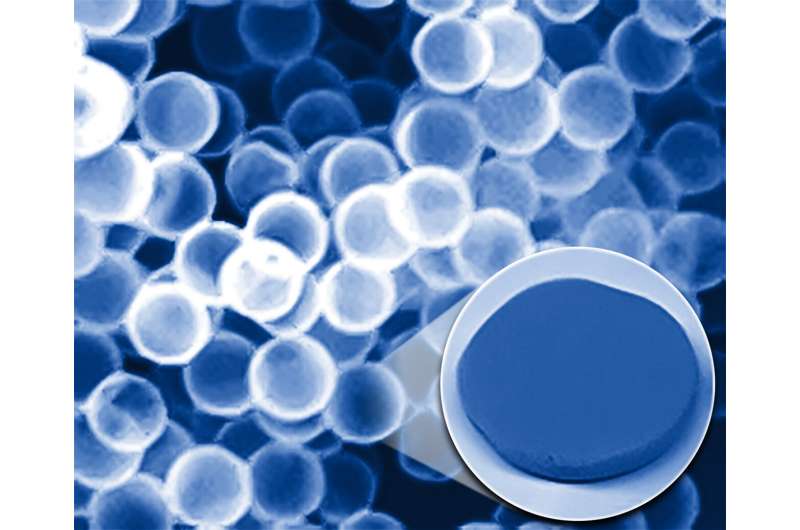

A thermal insulation composite from hollow silica particles mixed with cellulose fibers

Oak Ridge National Laboratory researchers demonstrated a process for producing a moisture-stable, lightweight thermal insulation material using hollow silica particles, or HSPs. Their study was published inRSC Advances.

Thermal materials insulate refrigerators, building envelopes, energy storage systems, fuel cells, heat exchangers and combined heat and power systems. Commonly made from glass fiber, mineral wool or polystyrene, these materials also require thick layers that take up significant space within building equipment and envelopes, which in turn lowers energy efficiency.

HSPs provide an alternative, but their nano-micrometer size and powder-based structure also make them more susceptible to moisture, difficult to transport and messy to use.

In a study, researchers made a thermal insulation composite by mixing cellulose fibers and HSPs in water, then pouring the mixture in molds and removing the water through a freeze-drying technique.

“We demonstrated that our composite is highly stable to moisture,” ORNL’s Diana Hun said. “This addresses the long-standing issue of using HSPs as thermal materials.”

Jaswinder Sharma et al, A lightweight thermally insulating and moisture-stable composite made of hollow silica particles, RSC Advances (2022). DOI: 10.1039/D2RA01561G

Citation:

A thermal insulation composite from hollow silica particles mixed with cellulose fibers (2022, September 8)

retrieved 8 September 2022

from https://phys.org/news/2022-09-thermal-insulation-composite-hollow-silica.html

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no

part may be reproduced without the written permission. The content is provided for information purposes only.

For all the latest Science News Click Here

For the latest news and updates, follow us on Google News.