Using the principle behind coffee ring effect in quantum dot arrays

If spilled coffee is not immediately wiped off, it leaves behind a stain where the edges are darker than the rest. This phenomenon is called the coffee ring effect. Using this principle, a POSTECH research team has recently developed a new method for arranging quantum dots (QDs) which are nanosized semiconducting crystals. This new simple method facilitates the development of display panels with up to 20 times higher resolution than the conventional ones.

A POSTECH research team—led by Professor Junsuk Rho of the Department of Mechanical Engineering and Chemical Engineering, professors HangJin Jo and Moo Hwan Kim of the Division of Advanced Nuclear Engineering and Department of Mechanical Engineering, Taeyang Han of the Division of Advanced Nuclear Engineering, and Ph.D. candidate Jaebum Noh in the Department of Mechanical Engineering—developed a QD array using a phenomenon that occurs when a suspension evaporates. Suspension refers to a liquid in which solid particles are dispersed and suspended as in muddy water, ink, or paint.

QDs, which are several nanometers in size, follow the flow of a fluid very well. Just as coffee stains are left when a drop runs on the side of a cup, when a suspension containing QDs evaporates, the particles automatically assemble in certain areas like the edge of a liquid drop induced by capillary flow.

Many attempts have been made to take advantage of this property, but acquiring brightness suitable for displays have been difficult. The cost of the product was also high because QDs were printed directly on the substrate using expensive equipment.

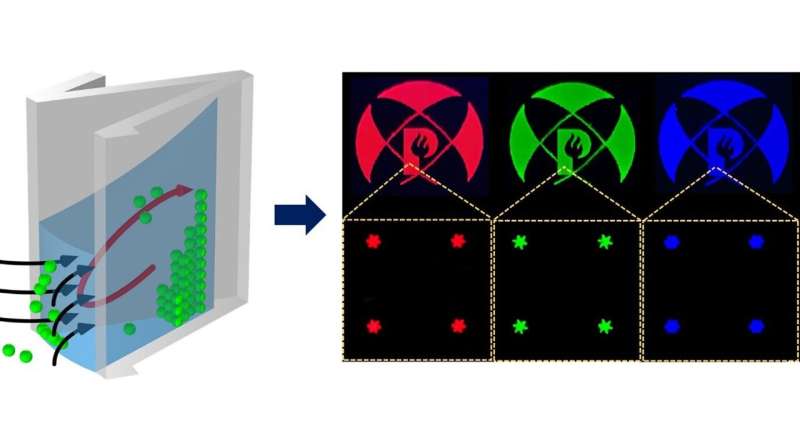

To overcome this limitation, the researchers arranged the QDs in the form of very small pixels during the suspension evaporation process using a V-shaped structure. When the liquid is poured and evaporated, the QDs are driven toward the inner tips of the V-shape and accumulate there.

The results revealed that the brightness of the QD pixels produced in this way was 20 times brighter than that of the control group and showed high uniformity rate of over 98%.

“Recently, the home appliance industry is using QDs in color filters in televisions for bright and natural images,” remarked professors Junsuk Rho and HangJin Jo. “Using the QD pixel array method developed in this study, bright QD pixels are created by simply spraying the suspension without expensive equipment, thus reducing the manufacturing cost.

The research was published in ACS Applied Materials and Interfaces.

International team uncovers mystery behind ‘coffee ring’ formation

Taeyang Han et al, Pixelated Microsized Quantum Dot Arrays Using Surface-Tension-Induced Flow, ACS Applied Materials & Interfaces (2021). DOI: 10.1021/acsami.1c14857

Provided by

Pohang University of Science & Technology (POSTECH)

Citation:

Using the principle behind coffee ring effect in quantum dot arrays (2021, November 24)

retrieved 24 November 2021

from https://phys.org/news/2021-11-principle-coffee-effect-quantum-dot.html

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no

part may be reproduced without the written permission. The content is provided for information purposes only.

For all the latest Science News Click Here

For the latest news and updates, follow us on Google News.